British bell manufacturer enjoying rush of fame in advance of Queen’s jubilee, Olympics

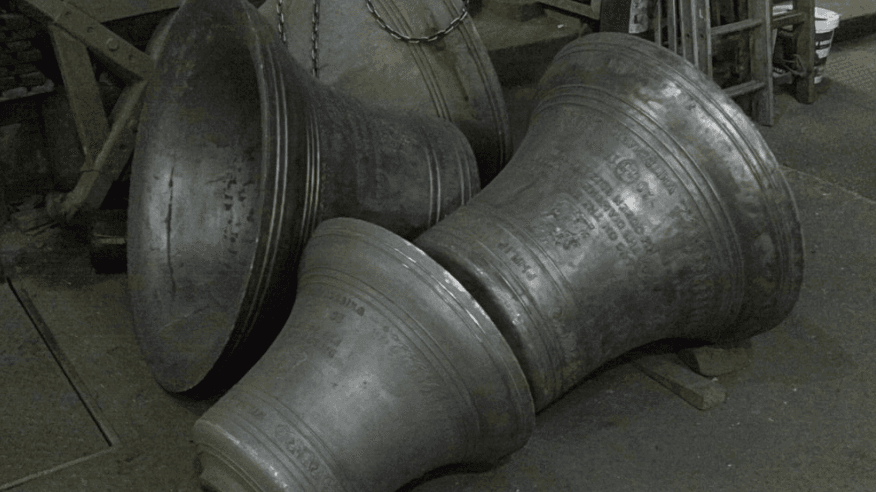

These bells, named Elizabeth, Phillip and William, will be rung during Queen Elizabeth’s diamond jubilee celebration. (Photo by Laura Lynch.)

As London gears up for a summer of celebrations and crowds, one sound is sure to capture the spirit of the city again and again.

Big Ben, the giant bell sitting at the Houses of Parliament, is just one among many attractions that mark the British capital. The bell itself was made at a foundry that’s more than four centuries old. This year, though, the foundry is experiencing a bit of a renaissance.

Entering the Whitechapel Bell foundry off a busy road in London’s east end, the first thing you will hear, not surprisingly, is a bell.

The entryway has a replica of a cross-section of Big Ben, more than six feet tall and more than nine feet wide.

Big Ben was created right here in 1858, but the foundry’s history is much older than that, boasts managing director Alan Hughes.

“The fact we have been doing this in the east end of London for well over 400 years means we must be doing something right,” Hughes said.

On the foundry floor itself, the men who craft the bells hew to ancient traditions, shoveling a pile of what looks like black dirt into a giant mixmaster. Bell founder Nigel Taylor knows the list of ingredients well.

“This is the loam and the loam is made up chiefly of yellow London clay, and goat’s hair, horse manure, sand and some straw,” Taylor said. “The recipe is certainly well over 1000 years old. The monks in England recommended wild boar manure because there were plenty of wild boar available at that time. Now there are a few wild boar, but not enough. So we have moved on to horse manure.”

Taylor has been a bellfounder for three decades — after deciding against a career as a tax inspector. He knows the intricacies that go into creating a bell that will ring loud and proud for centuries, just the right amount of water to mix with the loam and just the right mix of molten copper and tin that will be poured over the mold to make a bell.

Big Ben, Taylor said, is not even remotely worth all the fuss it creates.

“Big Ben is famous because of its sound but there’s no way you would describe it as a fine tone bell. It’s just a large bell,” Taylor said. “I’ve gotten used to it. As the world has gotten used to it. But you wouldn’t describe it as a fine tune bell.”

What has Taylor and the other workers here much more excited are the two special commissions they are working on this year. This week, they are putting the finishing touches on a series of eight bells to be rung as part of the Queen’s Diamond Jubilee celebration.

They are named after senior members of the royal family, with Elizabeth’s the largest and Henry – Prince Harry’s formal name – the smallest.

They’ll be ringing out across the Thames in June as they float down river on a specially built tower atop a barge leading a flotilla of a thousand boats.

Then, there’s that other bell – a very big bell, said Alan Hughes.

“Well there is this thing called the Olympic Games which has to be somewhere and where better than London and if it’s going to be London, where better than the east end, which is the greatest part of London,” he said. “I mean we’re in the east end so it has to be the greatest part of London. And in fact the Olympic site is only five miles from here. So yeah we’re providing a bell for the Olympics which is incredible. And no I can’t say much about it, but we are incredibly excited.”

Olympic officials have released some details.

At 27 tonnes, it will be the largest bell in Europe, twice the size of Big Ben. The bell will be placed at one end of the stadium and will ring to mark the very opening of the games, and will be inscribed with a quote from Shakespeare’s The Tempest, “Be not afeard, the isle is full of noises”.

Alongside these two high profile commissions, the foundry workers are busy with dozens of other bells destined for churches and city halls, along with smaller bells for town criers, bell choirs and pub managers who need to signal last call.

For the men who make them, there is an enduring pride and sense of history.

They crafted the Liberty Bell here — a bell that famously cracked. Nigel Taylor does not hesitate to defend the work of his foundry forefathers.

“Apparently it had a very rough crossing and we think they clocked it. That is they tied a rope to the clapper and pull the clapper up on to the bell and held the clapper against the bell which damped the sound and eventually it cracked and it was recast locally. The present bell is a very poor casting, it’s riddled with flaws and regrettably its cracked. It’s not our fault” said Taylor.

During the royal wedding last year, the bells of Westminster Abbey pealed across London as the ceremony ended.

Among them are two bells that were cast in the foundry in 1583. Alan Hughes said that demonstrates what a strange business he’s in; a product well made may never need to be replaced.

“In a sense a bell is like a wineglass, in that it’s very brittle. Which means if you treat it badly it might only last 30 seconds but if you treat it well and carefully, it will last forever.”

For the Whitechapel Foundry, business is good.

The oldest manufacturer in all of Britain is in the midst of a bit of a bell-building boom, and that is reason enough for them to smile when the chimes ring out this summer.