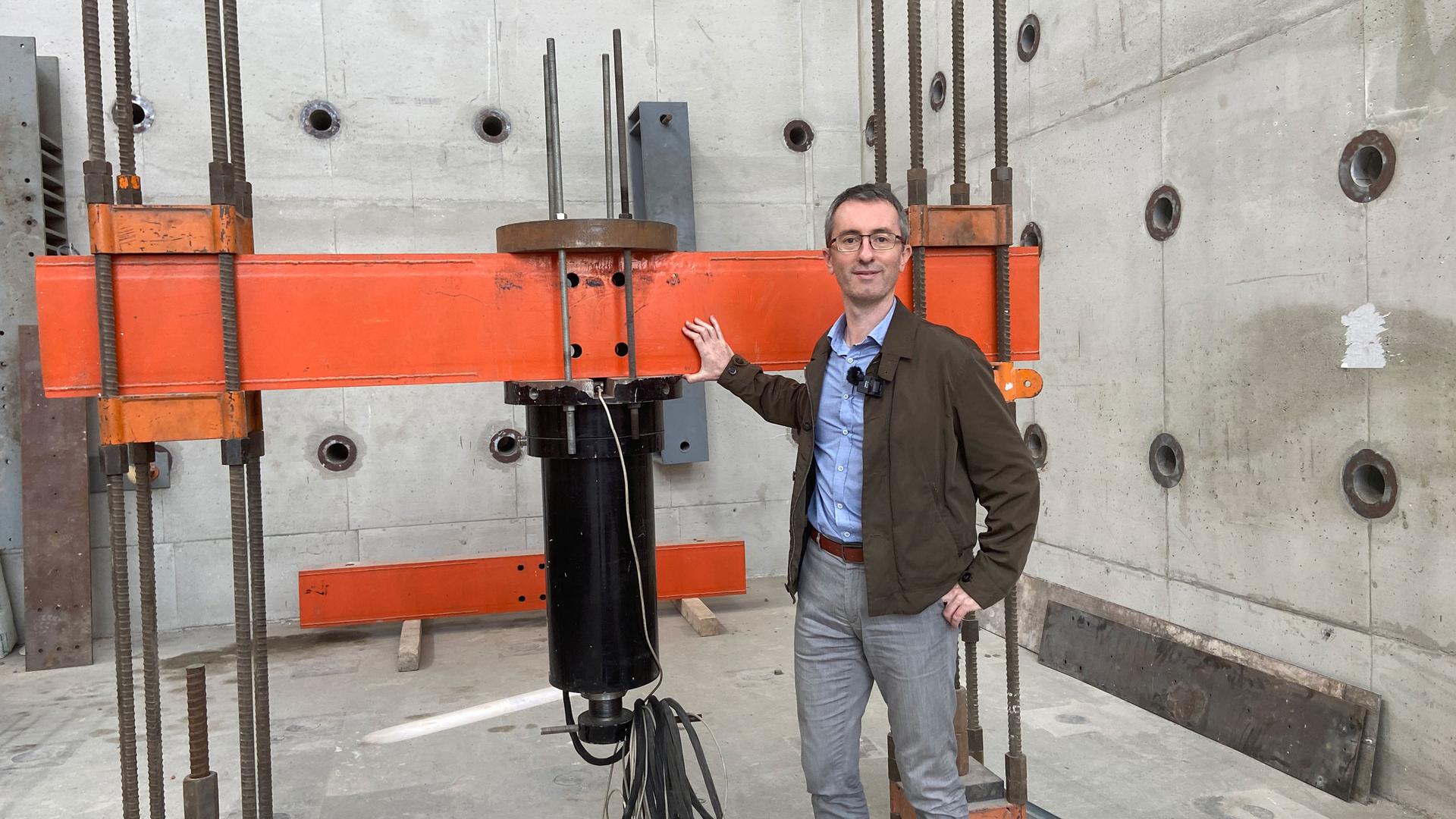

Spain’s Institute of Science and Concrete Technology laboratory sits inside a cavernous, concrete hanger on the campus of Valencia’s Polytechnical University. It hosts one of Europe’s largest disaster simulators — all kinds of them, according to lead scientist José Adam.

“Earthquakes, explosions, fire, landslides, floods,” he said. “These are the events we work on.”

Adam’s lab is getting attention after the deadly earthquakes that struck Turkey and Syria in February, which killed at least 50,000 people.

The experimental lab looks like a massive construction site. But there’s some high-tech gadgetry among the pallets of building materials and the steel cabling: a hydraulic jack in one corner that can apply tons of pressure on, say, a bridge pillar; another contraption tests how well a concrete wall stands up to fire; yet another jack applies seismic pressure against a recently erected brick hut.

The main aim here is to make buildings more resilient by improving “continuity” — how well the different parts of a building hold together.

“Continuity is a key aspect because if one of the columns collapses, the load of that column should be transferred to other elements,” Adam said.

Think of a building as a group of mountain climbers all connected by a safety rope. If one climber slips, the others can collectively stop the fall and prevent the climber from sliding away.

Adam’s team tests for continuity on full-scale buildings outside the city.

On a recent afternoon, they sent in a remote-controlled forklift to deliberately punch out a column on a two-story structure. The building sagged for a second, but didn’t collapse. The team of some 50 people erupted in applause.

But sometimes, collapse is unavoidable, the scientist explained. Take the truck bomb that brought down a full third of the Alfred P. Murrah Federal Building in Oklahoma City, Oklahoma, in 1995.

That tragedy was a seminal moment in structural design — the homemade bomb, he said, took out just three of the building’s many columns, yet it led to structural catastrophe due to the domino effect of collapsing sections. After that, engineers came up with the idea of a so-called “last line of defense” for buildings.

Adam is working on what is called “fuse segmentation,” essentially structural break points in the building. It’s a safety measure, and works just like electrical fuses in a home.

“You won’t see these fuses, because they are inside the structure.”

Under normal conditions, the fuses are structurally sound. But if one corner of a building begins to collapse, say, after a flash-flood, metaphorically speaking, the fuses will blow.

“It breaks this segment, separating the collapsing area from the rest,” he said. “This is a smart switch device.”

In other words, you can cut your losses. Almost like a lizard that can detach its own tail to escape predators.

The lab is still perfecting these structural fuses, but part of their genius is that they cost virtually nothing because it does not require bringing new materials or mechanisms to the construction process.

It’s a matter of strategically weakening certain parts of the building, which hold up under normal conditions but collapse under high stress.

“The construction sector is very conservative,” he said. “If you want to convince people to use a device, they won’t pay for it.”

Adam said he hopes this low-cost solution can be used everywhere one day, and not just in earthquake prone areas — with climate change, no building’s safety is guaranteed, because no one can predict the weather.

“For example, storms in places where you didn’t didn’t have storms in the past, or strong rainfalls or landslides in a place where maybe nothing happens now but in the future.”

But no matter how good building technology gets, if contractors don’t use it, then disasters like the quake in Turkey will continue to topple towers, and kill people, in large numbers.